-

Apexlink

Real Estate

-

DLS

General Insurance

-

DMV

Government

-

Entiger

Fintech

-

GIS Mapping

Gas & Petroleum

-

HMS

Employee Benefit

-

HAWA

Government

-

Harley

Community

-

IHG

Hotel & Tourism

-

Sparkseeker

Humane Tech

-

Track Ninja

Sports

-

Response Vision

Disaster Management

- Artificial Intelligence

- Application Services

- Automation Services

- Cyber Security

- Chatbot Experts

- Data Analysis

- Data Warehouse Services

- Machine Learning

- Digital Commerce Services

- Digital Transformation

- Infrastructure Service

- IT Support

- IT Consulting

- IT Outsourcing

- IOS Development

- Android Development

-

Cross Platform Development

-

Gaming App Development

When it comes to supply chain management, the one thing that every owner understands is that disruption may hit your operations without any warning. To efficiently tackle such situations, you need a smart approach.

Let us take an example to understand, suppose Matthew is the purchasing manager of an Original Equipment Manufacturing Company and is responsible for managing all the supply needs for the assembly operations. Due to a sudden strike by the workers at XYZ, their primary port on the East coast, assemblies are not moving to the next leg of the journey.

This has a direct impact on the functioning of the plant; as the levels of input stocks start depleting, there is a significant risk of production grinding to a halt and a shutdown of plant operations.

- Timeline on when will the plant run out of parts.

- Which assembly line will be affected?

- Is airlifting possible, or is there any other solution to help the fulfillment?

- Cost implications of these disruptions.

Let’s discuss the challenges Mathew might face in managing the disruptions.

Without an efficient framework, Mathew will be hard-pressed to find any viable solution that’ll help him prevent the shutdown. He needs hyper-connected automotive value supply chain software through which he will have an opportunity to manage the disruptions and mitigates the risk.

Now, Mathew’s managers have some questions that demand answers (You might also want some answers when it comes to your organization).

Challenges You Might Face In Your Supply Chain Optimization

It is a tedious task to identify & mitigate issues in supply chain management. Silos and black stores can create information barriers while sharing info within the organization and it makes it difficult for even the departments when it comes to predicting and identifying issues collectively. After the problems are identified, response time is usually too slow and when corrective actions are taken the OEM (Original Equipment Manufacturer) may not have the right tool to access the damage done. This inability can render any action useless.

The need for software is not limited to vehicle tracking in this complex system but is now being used throughout the value supply chain operation.

There are some tenets which will play a vital role in the logistics of the supply chain.

These tenets are:

- The growing digitization of the industry

- Use of smart robots

- An expressive and connected ecosystem

In the realm of logistics, it involves a daily collaboration of millions of IOT-enabled smart parts from many suppliers across the globe via multiple models of deliveries. There are some outside forces which showcase the need for robust supply chain processes framework. Some of the external forces are fluctuating currency, geopolitical storm, rising customer’s expectations, and volatile market conditions. With these forces in play, your supply chain business is in dire need of an efficient logistic framework to closely track the product flow.

For such a model to work, you need to make sure that it must be self-steered, not centrally-steered.

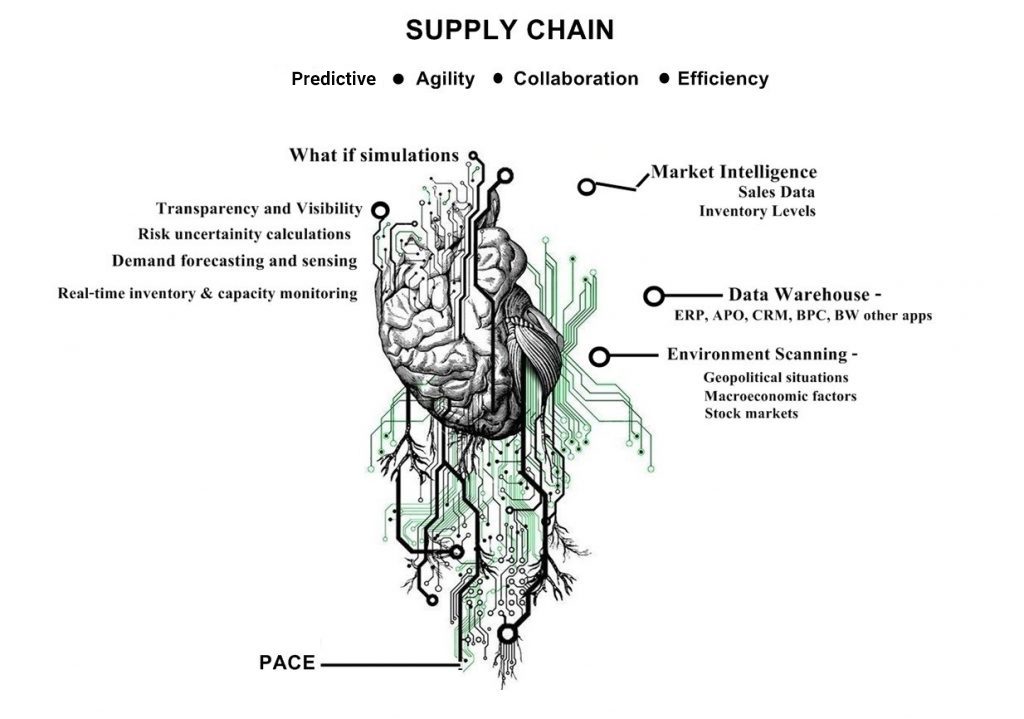

The Essence Of Digital Supply Chain: PACE

Can you imagine a healthy body without a properly functioning heart? It is same for the operations of Supply chain. A fully operational and robust supply chain relies on a smoothly functioning logistics. With PACE framework, you can ensure that your logistics is functioning seamlessly.

What is PACE!!!

- Predictive planning to balance supply and demand.

- Agility for timely response to unexpected changes and handling disruptions cost-efficiently.

- Collaboration between the departments such as sales, after-sales, procurement, manufacturing, and suppliers.

- Efficiency in reducing the supply chain cost and manages any disruptions and other complexities.

Let’s get back to Mathew’s predicament.

How is this PACE framework going to help Mathew? Mathew can use this framework to identify and mitigate all the disruptions that are affecting the supply chain model of his organization.

To make sure that this model works fine, Mathew will need sufficient inputs from both demand and supply sides. Once he gets all the data, this model will help his organization to mitigate all the issues timely by generating all the what-if scenarios.

Which Demand-side inputs does he need?

- Company’s production schedule, which must include the exact production dates and times.

- Material’s bill to identify the number of parts required.

- Detailed open orders, including the part numbers, quantity, planned delivery date, and time.

- Receipt of parts showcasing the receiving status of a particular type of parts.

- Input on the availability of each part at every location.

Which Supply-side inputs does he need?

- ETA (revised) updating the time of arrival.

- Serial numbers of the silos or container box on the shipping vessel.

- All the part numbers and quantity of each shipping container.

With the above model, Mathew can easily monitor the supply status and also anticipate any future disruptions and mitigate them as well.

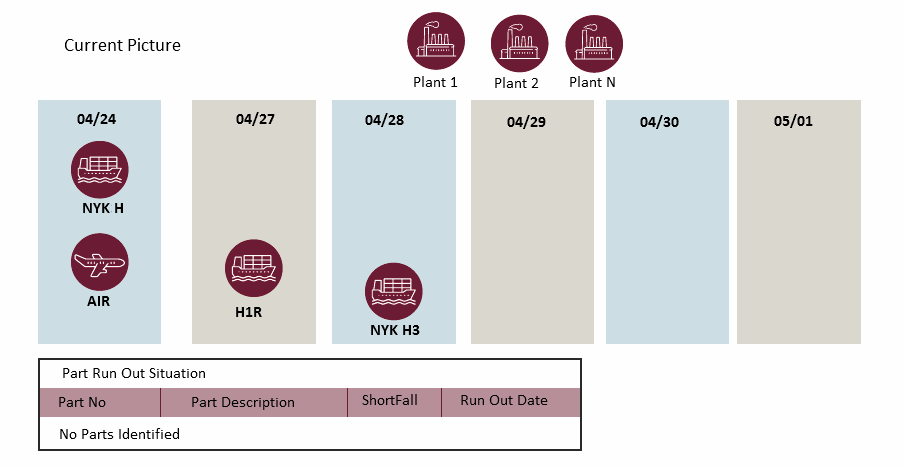

Theoretical Assessment Of PACE Framework

Let’s assume that Mathew’s dashboard (which is powered by PACE framework) is capturing the current situation. All is going according to the plan, i.e. all the vessels and carriers are arriving on time. It showcases that no part shortages are expected and all the plants are expected to run smoothly.

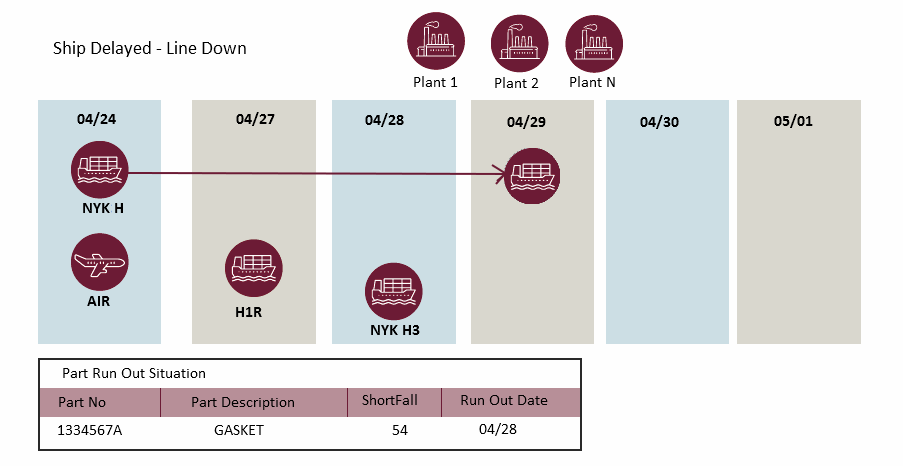

In logistics, these situations tend to change rapidly. Here comes the power of the PACE model. Whenever there is a disruption, the PACE enabled dashboard will update the ETAs accordingly.

With such authority, Mathew can quickly check all the vehicle variants that may be impacted. He can also check if the parts are available at some other location or if he needs to expedite containers once they reach their destination.

Hence the PACE-powered software-enabled Mathew to meet his current objectives.

- Predictive system to anticipate a situation before it occurs.

- Mathew’s organization will be able to handle the situation with agility.

- Mathew can easily collaborate with logistics providers with the right ETAs.

- Mathew can selectively expedite critical silos or containers efficiently instead of blocking the whole shipments.

Seasia’s Approach In Logistics Software Development: PACE-Inspired

We at Seasia believe that with growth in business, complexity is common. To manage supply chain operation, you need to focus your efforts both on inbound and outbound operations. The Software development process followed by Seasians will enable you to take the supply chain logistics to a whole new level.

Here have a look at what we have for your logistics operations.

For your Supply Chain Governance

- We will study and understand your organization’s vision in making logistics elements.

- Strategic changes for your software to gain more insights.

- Work on providing more transparency in your complete value chain.

For your Supply Chain Alignment

- We will link internal production with external suppliers.

- We will enable you with a dashboard that will give you a detailed breakdown of total landed cost.

For your Supply Chain Optimization

- Circulation of valuable information on a real-time basis throughout the supply chain network.

- We will automate and integrate all your company-wide processes and applications.

To tackle all the complexities, we believe that OEMs (Original Equipment Manufacturers) must avoid the forecast-driven approach to the logistics and move towards the demand-driven approach. All this is possible with our unique PACE-driven framework.

Contact us now, and let’s discuss how our PACE-driven framework can help your organization.

Artificial Intelligence

Artificial Intelligence

Blockchain

Blockchain Cloud Computing

Cloud Computing Infrastructure

Services

Infrastructure

Services Metaverse

Metaverse QA

Automation

QA

Automation UI/UX

UI/UX